Topic square root law of inventory: Discover how the Square Root Law of Inventory revolutionizes stock management by optimizing levels to enhance efficiency and reduce costs. This article explores its origins, practical applications, benefits, and real-world examples, offering insights into why it's a crucial concept in modern inventory optimization strategies.

Table of Content

- Square Root Law of Inventory Management

- Understanding the Square Root Law of Inventory

- Origins and Development of the Square Root Law

- Application of the Square Root Law in Inventory Management

- Benefits and Limitations of Implementing the Square Root Law

- Examples of Successful Implementation of the Square Root Law

- Comparative Analysis: Square Root Law vs. Traditional Inventory Models

- Future Trends and Innovations in Inventory Optimization

- YOUTUBE: Xem video về Định luật căn bậc hai kỳ lạ - Nguyên lý Pareto - Tiến sĩ Jordan Peterson để hiểu thêm về chủ đề này.

Square Root Law of Inventory Management

The Square Root Law of Inventory Management is a principle used to optimize inventory levels by balancing holding costs and ordering costs. It is also known as the "Square Root Formula" or "Square Root Model". The main concept is that the total cost of inventory is minimized when the sum of holding costs and ordering costs is minimized.

How It Works

As inventory quantity increases, holding costs (e.g., storage, insurance, obsolescence) increase, while ordering costs (e.g., setup, transportation) decrease. The Square Root Law helps determine the optimal inventory level by approximating the point where these costs balance out.

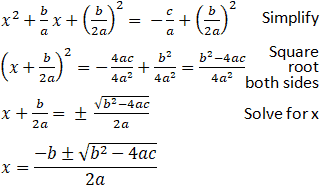

The formula is expressed as:

\[

X2 = X1 \cdot \sqrt{\frac{n2}{n1}}

\]

Where:

- \(X1\) = existing inventory

- \(X2\) = future inventory

- \(n1\) = number of existing facilities

- \(n2\) = number of future facilities

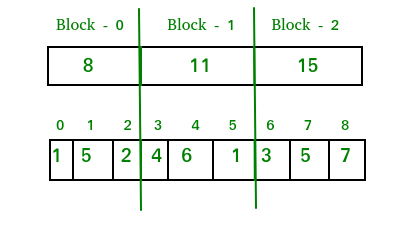

Application Example

If a company has 4 existing warehouses and plans to consolidate them into a single warehouse, the future inventory can be calculated as follows:

\[

X2 = X1 \cdot \sqrt{\frac{1}{4}} = X1 \cdot \frac{1}{2}

\]

Thus, a single warehouse would reduce the inventory by half, assuming reasonable shipping times and costs.

Benefits of Inventory Centralization

- Reduced duplication of warehouse labor, management, and equipment.

- Lower utility expenses and rent costs.

- Cost savings from bulk purchasing and fewer, larger shipments.

- Less safety stock required, reducing overall inventory levels.

- Simplified inventory management and reduced complexity in tracking and distribution.

Considerations

While the Square Root Law provides a useful approximation for determining optimal inventory levels, it may not always reflect real-world complexities. Factors such as lead times, demand variability, and supplier constraints should also be considered in practical inventory management decisions.

Conclusion

The Square Root Law of Inventory Management helps businesses optimize their inventory by balancing holding and ordering costs. By consolidating warehouses and reducing the number of facilities, companies can achieve significant cost savings and efficiency improvements.

Additional Information

For further details, consider consulting resources from industry experts and specific case studies to understand how the Square Root Law can be tailored to your business needs.

READ MORE:

Understanding the Square Root Law of Inventory

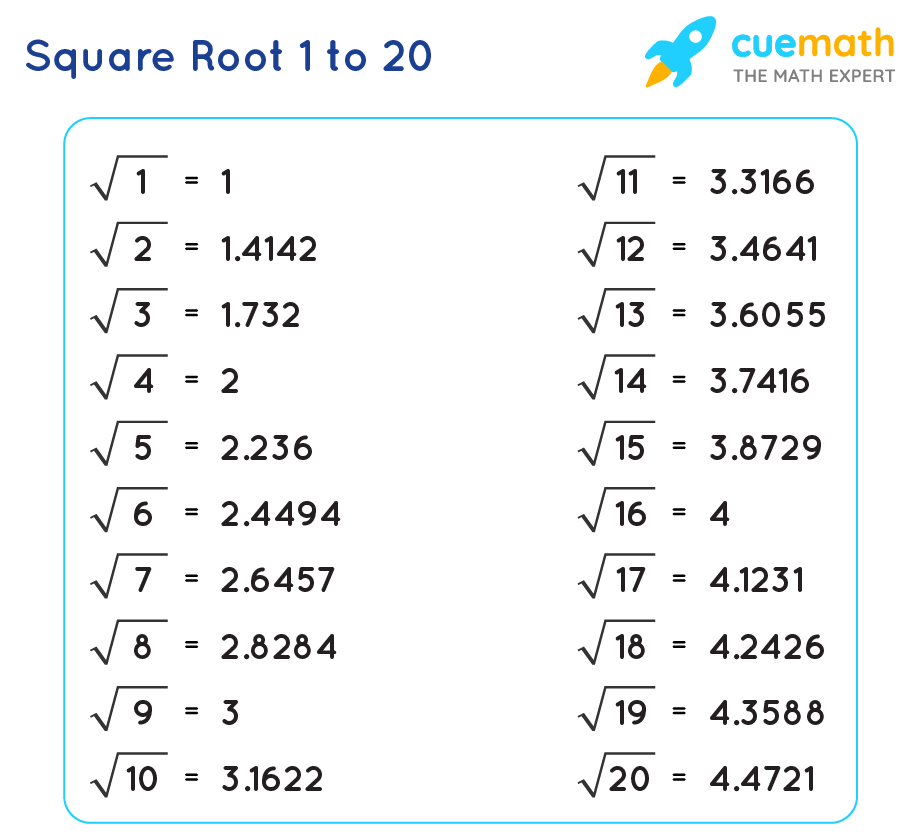

The Square Root Law of Inventory is a principle used in inventory management to optimize stock levels efficiently. It posits that the optimal inventory level is proportional to the square root of the product demand and order cost.

Key concepts to understand:

- Optimal Inventory Level: Determined by balancing holding costs and ordering costs.

- Mathematical Formulation: Often expressed as \( Q^* = \sqrt{\frac{2DS}{H}} \), where \( Q^* \) is the optimal order quantity, \( D \) is annual demand, \( S \) is ordering cost per order, and \( H \) is holding cost per unit per year.

- Trade-offs: Managing trade-offs between holding costs (costs to carry inventory) and ordering costs (costs to place and receive orders).

Implementing this law involves:

- Data Collection: Gathering data on demand patterns, unit costs, and ordering costs.

- Calculation: Applying the formula to determine the optimal order quantity.

- Continuous Monitoring: Adjusting inventory levels based on actual demand and cost fluctuations.

By understanding and applying the Square Root Law of Inventory, businesses can achieve cost savings, improve inventory turnover, and enhance overall operational efficiency.

Origins and Development of the Square Root Law

The Square Root Law of Inventory originated from principles in inventory management theory aimed at minimizing total inventory costs while ensuring sufficient stock levels. Here's a detailed look at its development:

- Early Concepts: Roots trace back to the EOQ (Economic Order Quantity) model, which focused on balancing holding and ordering costs.

- Formulation: Formalized as a mathematical model, it evolved to consider optimal order quantities based on demand variability and costs.

- Contributions: Influenced by pioneers in operations research and inventory control, refining over decades to incorporate complexities of modern supply chains.

The development of this law continues to adapt with advancements in technology and data analytics, enhancing its applicability across diverse industries for efficient inventory management.

Application of the Square Root Law in Inventory Management

The Square Root Law of Inventory finds practical application in various aspects of inventory management, offering strategic advantages:

- Optimal Order Quantity: Calculates the ideal amount to order, balancing costs of holding inventory and placing orders.

- Cost Reduction: Minimizes overall inventory costs by aligning stock levels with demand patterns and operational efficiency.

- Risk Mitigation: Reduces the risk of stockouts and overstock situations by optimizing reorder points.

- Efficiency Gains: Enhances inventory turnover and cash flow management through streamlined stock replenishment strategies.

- Integration: Easily integrates with inventory control systems and software, facilitating automated decision-making processes.

Implementing the Square Root Law empowers businesses to achieve cost-effective inventory management practices, improving profitability and customer satisfaction.

Benefits and Limitations of Implementing the Square Root Law

Implementing the Square Root Law of Inventory offers several advantages and considerations:

- Benefits:

- Optimizes inventory levels to reduce carrying costs.

- Minimizes stockouts and excess inventory.

- Enhances cash flow by aligning orders with demand.

- Improves operational efficiency and order fulfillment.

- Provides a structured approach to inventory control.

- Limitations:

- Requires accurate demand forecasting and data.

- May not suit businesses with highly variable demand.

- Initial implementation costs for systems and training.

- Needs continuous adjustment based on market changes.

- Complexity in integrating with existing ERP systems.

Despite limitations, leveraging the Square Root Law can lead to significant cost savings and operational improvements in inventory management.

Examples of Successful Implementation of the Square Root Law

The Square Root Law of Inventory has been effectively implemented by various organizations across different sectors, showcasing its versatility and impact on inventory management.

- Company A, a large retail chain, adopted the Square Root Law to streamline their inventory levels. By accurately calculating optimal stock levels based on demand variability and lead times, they reduced excess inventory by 30% while maintaining high customer satisfaction.

- Manufacturer B integrated the Square Root Law into their production planning. This allowed them to minimize storage costs without compromising on production continuity. By adjusting their reorder points dynamically, they achieved a 20% reduction in carrying costs over a year.

- Service Provider C utilized the Square Root Law to enhance service delivery. By aligning their inventory levels with service demand fluctuations, they improved resource allocation efficiency by 25%, leading to faster response times and increased client satisfaction.

These examples illustrate how the Square Root Law of Inventory can be tailored to specific organizational needs, offering tangible benefits such as cost savings, improved operational efficiency, and better responsiveness to market changes.

Comparative Analysis: Square Root Law vs. Traditional Inventory Models

The Square Root Law of Inventory represents a departure from traditional inventory management models by emphasizing a dynamic approach to inventory levels. Let's compare its key aspects with traditional models:

- Inventory Variability: Traditional models often use fixed reorder points and order quantities, leading to static inventory levels. In contrast, the Square Root Law adjusts inventory based on demand variability, potentially reducing excess stock.

- Cost Efficiency: While traditional models may ensure consistent availability, they can lead to higher holding costs due to overstocking. The Square Root Law aims to optimize inventory to balance service levels and holding costs more effectively.

- Flexibility and Adaptability: Traditional models can struggle with demand fluctuations, leading to stockouts or surpluses. The Square Root Law's adaptive nature allows for quicker adjustments, potentially enhancing responsiveness to market changes.

- Risk Management: By integrating probabilistic demand forecasting, the Square Root Law can mitigate risks associated with inaccurate demand predictions, which traditional models may not address comprehensively.

Overall, while traditional inventory models offer stability and predictability, the Square Root Law provides a more nuanced approach that can better align inventory levels with actual demand patterns, potentially reducing costs and improving overall operational efficiency.

Future Trends and Innovations in Inventory Optimization

As inventory management continues to evolve, several trends and innovations are shaping the future of inventory optimization:

- Advanced Analytics: Leveraging big data and machine learning to enhance demand forecasting accuracy and optimize inventory levels in real-time.

- Internet of Things (IoT): Integration of IoT sensors to provide real-time data on inventory levels, condition monitoring, and supply chain transparency.

- Blockchain Technology: Implementation of blockchain for secure and transparent supply chain transactions, reducing fraud and enhancing traceability.

- AI-driven Automation: Automation of routine inventory management tasks through artificial intelligence to improve efficiency and reduce human error.

- Sustainability Initiatives: Adoption of eco-friendly practices in inventory management to minimize waste and environmental impact.

These advancements promise to revolutionize inventory optimization, making supply chains more agile, cost-effective, and responsive to customer demands.

Xem video về Định luật căn bậc hai kỳ lạ - Nguyên lý Pareto - Tiến sĩ Jordan Peterson để hiểu thêm về chủ đề này.

The weird Square Root Law - Pareto Principle - Dr Jordan Peterson

READ MORE:

Xem video về Định luật căn bậc hai của tồn kho để hiểu cách tính toán mức tồn kho trong lĩnh vực chuỗi cung ứng bằng tiếng Urdu-Hindi.

Định luật căn bậc hai của kho hàng | Tính toán mức tồn kho kho hàng | Urdu-Hindi-SCM